In harsh and demanding environments, the reliability of power supplies often depends on their resistance to dust and moisture. This blog demystifies Ingress Protection (IP) ratings, helping engineers and product designers understand how to interpret them and what the numbers mean. We’ll explore typical IP ratings across industries Bel serves, such as industrial, transportation/eMobility, and consumer electronics, and explain how these requirements influence power supply selection and design. We also outline engineering strategies used to meet higher IP standards, including sealing techniques, specialized enclosures, and conformal coatings.

Why IP Ratings Matter in Power Supply Design

When engineers develop designs for use in simple and controlled settings, such as homes and offices, they rarely must consider the complexities of their environment. Most off-the-shelf parts are sufficient, and minimal thought is given to factors such as temperature, humidity, pressure and moisture.

However, when designing for more demanding environments, such as industrial facilities, marine systems, and outdoor equipment, numerous factors come into play that must be carefully considered. Among these, the IP rating of a component or device is one of the most critical specifications.

What Is an IP Rating? How Ingress Protection Codes Define Power Supply Durability

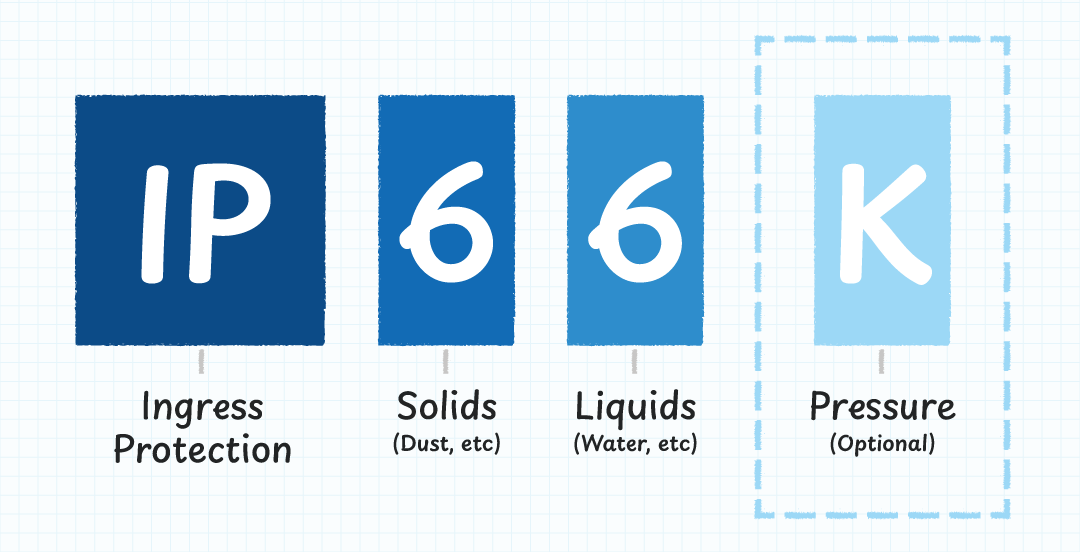

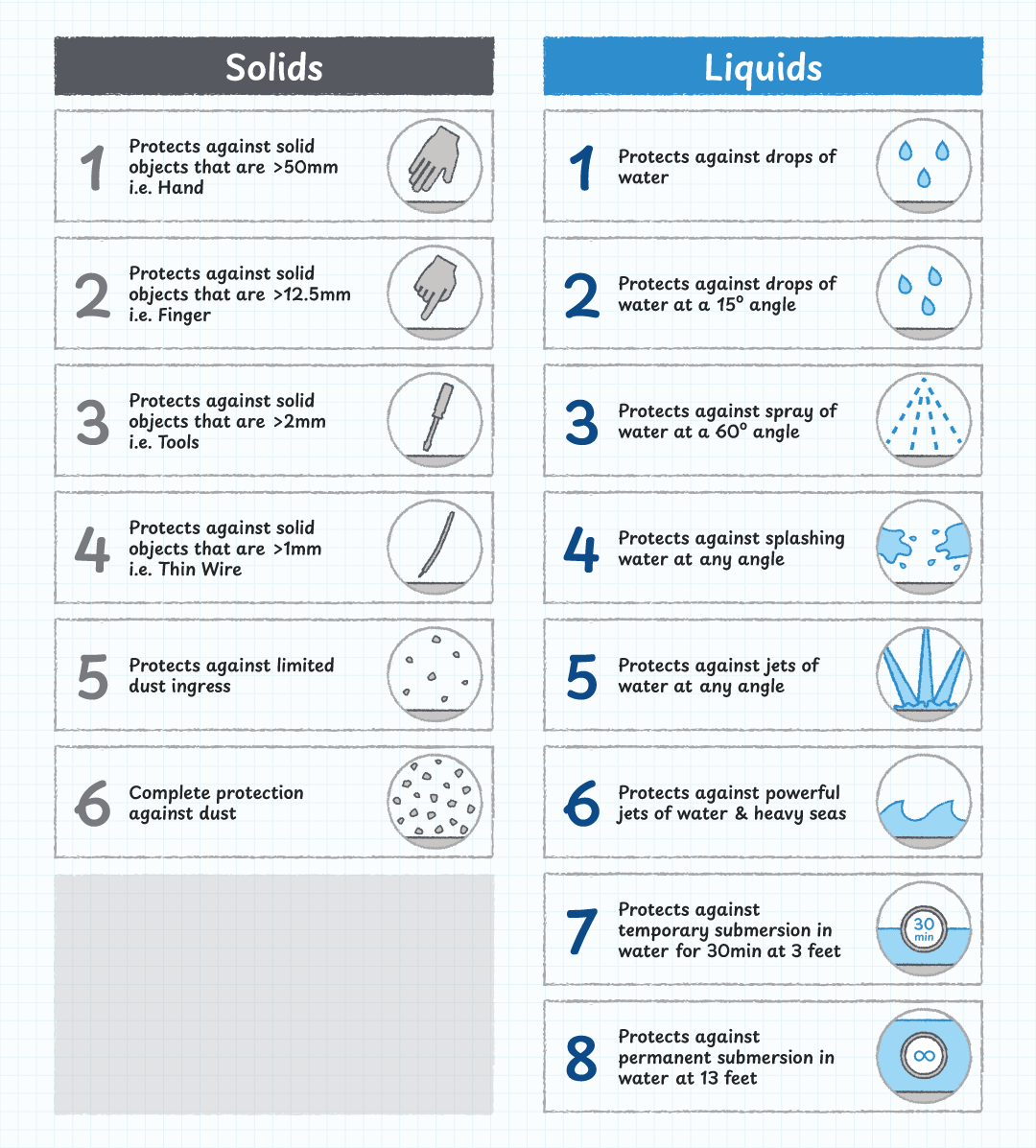

An IP rating consists of two numbers, each representing a different level of protection, with the first digit indicating the degree of protection against solid particles, and the second digit indicating the level of protection against liquids.

As an example, a device with an IP rating of 30 would be protected against solid particles with a diameter of 2.5mm or greater but would not be able to protect against any degree of liquid ingress. A device with a rating of 68, however, would be able to withstand significant amounts of dust and liquid, including complete immersion in water.

Low Exposure vs High Exposure Use Cases

Arguably, IP ratings are one of the most important factors in electronic design as electronic systems are almost always vulnerable to moisture and dust. Devices designed for clean, dry environments may function reliably with basic protection. However, systems used in kitchens, manufacturing plants, or marine environments require much higher protection levels.

Low-Exposure Use Cases: Devices in household settings may only need IPX4, which resists splashing water.

High-Exposure Environments: Systems in car washes or processing facilities may require IPX9K, a rating capable of withstanding high-pressure, high-temperature water jets.

Note: The "X" in an IP rating (e.g., IPX4) indicates that no data was provided for that particular type of protection (solid or liquid), not necessarily that there is no protection. This placeholder is often used when only one type of ingress resistance is tested or relevant.

But water is not the only factor that engineers need to consider when designing electronic circuits. Dust can also be a major issue, especially in applications where moving parts are involved. For example, switches, levers, and locks can all be affected by the presence of dust, leading to malfunction or complete system failure. Thus, engineers must consider what they can expect from their environment in the worst-case scenario and choose IP ratings accordingly.

Industry Specific IP Rating Requirements for Power Supplies

The requirement for IP ratings varies significantly across different industries, primarily due to the environment itself being the determining factor in the level of protection needed.

To start, industrial sites involved with the production of powders require high dust protection ratings to prevent the accumulation of dust particles in sensitive areas (such dust can also become highly explosive). Industrial facilities that deal with moisture and water will also necessitate high liquid ratings to protect electronic circuits. In more extreme industrial cases, such as mining facilities, both dust and water protection are essential, as these environments can be severely harsh (corrosive compounds, abrasives, and liquids).

In medical settings, high dust protection is crucial to maintain sterile environments, while power systems that interact with humans require elevated IP ratings to prevent short circuits and electrocution in the event of liquid contact (this is especially true for wearable medical devices).

The automotive industry also demands high IP ratings to safeguard against dust and dirt from roads, as well as rainwater that can compromise sensitive components. Marine systems, being exposed to both dust and saltwater, necessitate the highest IP ratings to guarantee the reliability of electronic equipment.

However, when selecting an IP rating for a device, it is also essential to consider the conditions under which a device may become exposed to, even for brief moments of time. One such example would be heavy machinery and food processing equipment that are not exposed to water jets during normal operation, but which are subjected to those conditions during cleaning.

How to Design for High IP Ratings: Enclosures, Sealants, and Coatings

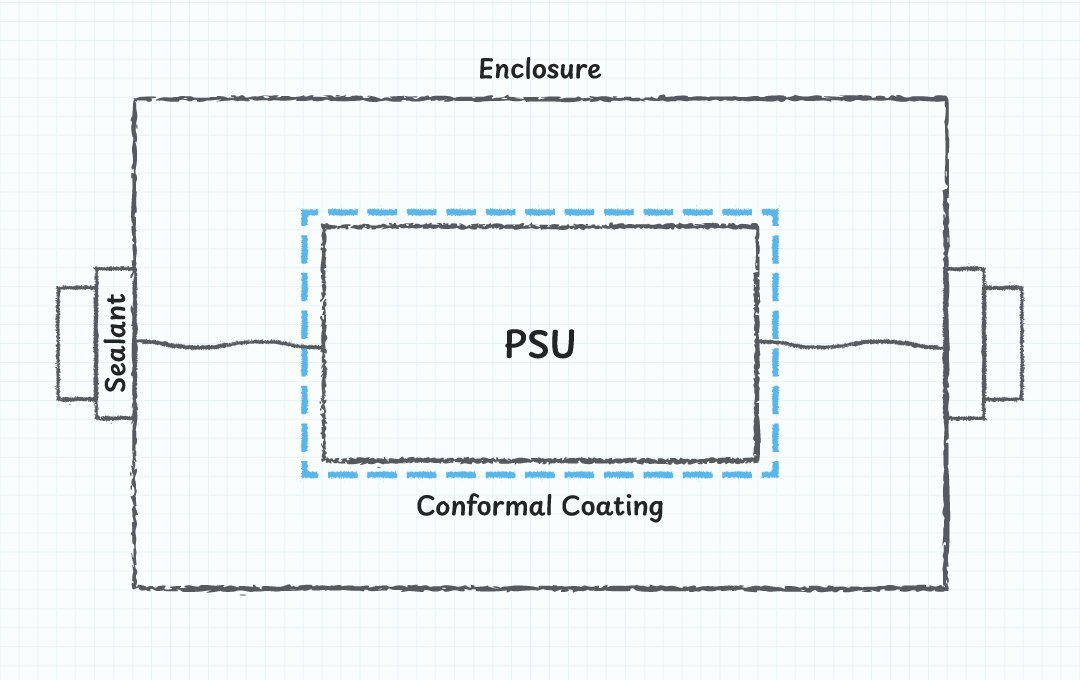

Engineers that have been tasked to increase the IP rating of a device can do so using numerous methods, but the three common approaches are enclosures, sealants, and coatings.

Enclosures: Enclosures can prevent exposure to dust and indirect water splashes from entering the device by providing a physical barrier. While enclosures are excellent for providing physical protection, if used on their own, they can struggle to provide high degrees of IP protection.

Sealants: Sealants around the seams and seals of enclosures can help engineers achieve the highest IP ratings thanks to their ability to seal all gaps and fittings. Sealants are also excellent for enclosures that need to allow internal access, which is massively beneficial for both manufacturing and maintenance.

Conformal Coatings: Conformal coatings are special chemical sprays that cover the entire surface of a device. These coatings can be used to protect devices that are fully submerged in water and can also be used to protect devices from dust and other contaminants. However, their major downside is that they can't be used with gas and liquid sensors, requiring sticker covers during spraying.

How IP Ratings Impact Power Supply Performance, Size, and Longevity

IP ratings are essential for ensuring the reliability and performance of power supplies, but increasing the IP rating of a design can introduce several challenges.

The first, and arguably the most significant, is its impact on thermal performance. As the IP rating of a device increases, the level of protection offered against solid objects and water also increases, but this comes at the cost of reduced airflow. In many power supplies, airflow is essential for dissipating heat, meaning that increased IP ratings can result in reduced thermal performance.

This reduction in thermal performance can then have a range of negative consequences, with the most significant being a reduction in the maximum power density of the supply. A reduced power capability will either require the size of the power supply being increased, or the efficiency of the supply being reduced in order to prevent overheating. Either of these options have a negative impact on the overall performance of the supply, as well as the cost of the design.

Secondly, the increased temperatures caused by reduced airflow also has a negative impact on operating life. Increased temperatures accelerate the rate of component degradation, which increases the risk of catastrophic failure. Thus, high IP ratings can indirectly result in increased downtime, along with an increase in system cost as power supplies are repaired and/or replaced.

Finally, increasing the IP rating on a design can also make it more challenging to perform repairs and maintenance. As high IP ratings often come with sealants, coatings, and complex fittings, it can be difficult to access the internal components of a high IP power supply without risking the IP rating. Thus, such power supplies might need a complete replacement, further increasing the system cost.

How to Select the Right Power Supply Based on IP Rating Requirements

Selecting a power supply while considering IP is no easy task, and many factors come into play, including power rating, environment, maintenance, and certifications.

As the maximum output power of a power supply may be reduced for high-IP-rated enclosures, it is best to choose a supply with greater power capability than what the system nominally requires. By doing this, the power supply can always meet the power demands of the end application while also providing a degree of headroom for any unexpected increases in power consumption.

Environments that demand high-IP ratings often come with strict standards for connectors, cable glands and terminations. As such, it is critical that the power supply selected offers sealed, shrouding, or locking connectors that meet the same (or higher), IP level as the installation.

Common IP Ratings and Their Applications

| IP Rating | Solid Protection (1st Digit) | Liquid Protection (2nd Digit) | Typical Use Case |

|---|---|---|---|

| IP54 | Limited dust ingress; not fully sealed | Protection from water spray from any direction | Indoor tools and control panels |

| IP65 | Completely dust-tight | Protection from low-pressure water jets | Industrial automation enclosures |

| IP66 | Completely dust-tight | Protection from high-pressure water jets | Outdoor LED displays, marine lighting |

| IP67 | Completely dust-tight | Protection from immersion up to 1 m | Field-deployed sensors, outdoor cameras |

| IP68 | Completely dust-tight | Protection from prolonged immersion | Submersible equipment, marine systems |

| IP69K | Completely dust-tight | Protection from high-temperature, high-pressure steam jets | Food processing equipment, vehicle wash systems |

Table 1: Common IP Ratings and Their Applications

In addition to the physical characteristics of the power supply, it is also important to consider the maintenance requirements of the system. If regular access to components is expected, it may be beneficial to choose modular solutions that allow for easy replacement without the need for extensive disassembly.

For demanding environments, it is also essential to evaluate the certifications and test results provided, especially for applications with strict criteria (medical, aerospace etc.). Relying on an IP rating for a specific environment can be problematic, due to differences in testing and requirements, which is why it is always best to select power supplies that have been designed and tested in accordance with a particular standard such as IEC 60529.

While high-IP-rated supplies may be ideal for the most demanding environments, they often come with increased cost, weight, and complexity, which can negatively impact product competitiveness. Because of this, it may be beneficial for engineers to match IP protection to actual requirements, rather than over-engineering solutions.

Finally, engineers should consider whether the power supply has been specifically designed with ruggedisation features beyond just IP protection. Features such as vibration resistance, protection against corrosion, and extended temperature ranges can all contribute to the long-term reliability of the system and will often be just as important in high-risk environments (automotive etc.).

Step-by-Step Guide: Selecting Power Supplies for IP-Rated Applications

- Determine Power Requirements: Identify the system’s nominal power demand, then choose a supply with additional capacity to compensate for power derating in sealed or high IP-rated enclosures.

- Assess Required IP Rating: Match the IP rating to the actual environmental conditions. Avoid over-specifying. Select the minimum rating necessary to meet protection needs without increasing system cost or complexity.

- Ensure Connector Compatibility: Verify that connectors, cable glands, and terminations are sealed or shrouded and rated to the same or higher IP level as the enclosure.

- Consider Maintenance Access: If routine maintenance or replacement is expected, prioritize modular power supplies that allow for easy access and reduced downtime.

- Confirm Compliance with Industry Standards: Select units tested to recognized standards such as IEC 60529. This is particularly critical for regulated industries like medical, aerospace, and defense.

- Evaluate Environmental Ruggedness: Beyond IP protection, look for design features such as corrosion resistance, vibration tolerance, and extended temperature operation.

- Balance Cost, Size, and Functionality: Weigh the benefits of enhanced IP and rugged features against potential trade-offs in unit size, weight, and budget.

The Importance of Reliable Power Supplies in Dust and Water Prone Environments

When designing electronic systems, engineers must account for numerous critical factors, of which, ensuring the appropriate IP rating is arguably one of the most important. While IP ratings may seem straightforward, choosing a power supply to meet an application’s IP requirements can be a complex and challenging task.

To mitigate these challenges, engineers should prioritize selecting power supplies from reputable manufacturers that offer solutions with the necessary IP ratings for their applications. While choosing a more robust power supply may provide additional protection, it is essential to strike a balance between performance and cost.

By selecting a trusted brand for power supplies with the required IP ratings, engineers can ensure the reliability and efficiency of their systems, ultimately leading to successful product development and deployment.

Explore Bel’s range of IP67/IP68-rated power supplies, engineered for industrial, medical, and marine environments.

.png)