Why Ethernet is Evolving for Harsh Environments

Ethernet has become the global standard for local area networks (LANs), cloud data centers, and, increasingly, industrial environments. Its combination of high data throughput, flexible network topology, and low cost makes it ideal for connecting a wide variety of devices.

In industrial settings, however, Ethernet faces unique challenges. Factory floors, transportation systems, and energy infrastructure expose cables and connectors to extreme temperatures, vibration, electromagnetic interference (EMI), moisture, and dust. These conditions demand more than what commercial Ethernet was originally designed to handle.

To meet these demands, Industrial Ethernet has emerged as a ruggedized, reliable networking solution. It maintains the core benefits of Ethernet (high-speed communication and easy scalability) while adding enhanced mechanical durability, environmental sealing, and support for time-sensitive communication protocols.

This article explores the fundamentals of Industrial Ethernet, its advantages over commercial implementations, and how Integrated Connector Modules (ICMs) simplify the deployment of power and data networks in demanding environments.

Why RJ45 Became the Standard for Ethernet

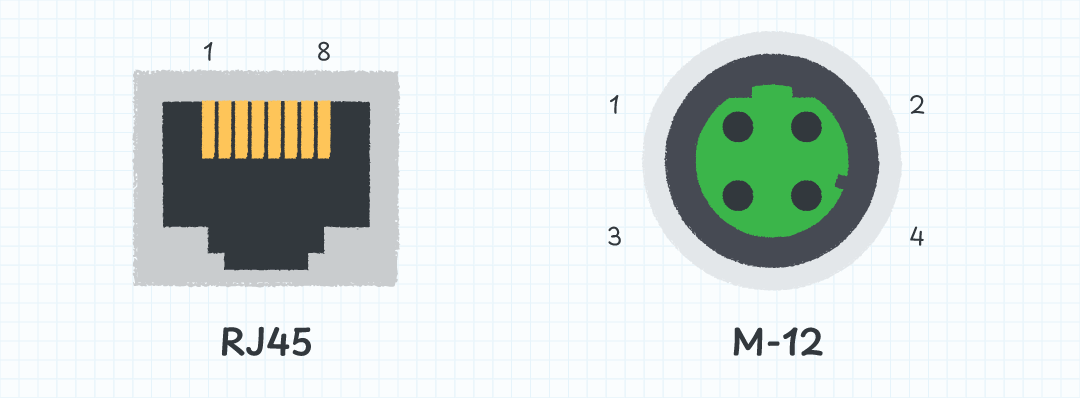

Among all the connector technologies developed over the past few decades, none have had the enduring impact of the RJ-series, particularly the RJ45 connector. Originally developed for telephone systems, RJ-style connectors quickly found their place in data communications due to their small form factor, reliable latching mechanism, and ease of use.

The RJ45 Connector is Now Synonymous with Ethernet. Its keyed design prevents incorrect mating, and the use of twisted-pair cabling helps cancel electromagnetic interference, enabling long-distance, high-bandwidth data transmission over copper. This made RJ45 a substantial improvement over earlier connector styles like DB-9 and DB-25, which were bulkier, lacked standardization, and were more prone to signal degradation at high speeds.

The global dominance of RJ45 in Ethernet systems is no accident. It offers the ideal balance of performance, cost, and usability for both commercial and industrial applications. In fact, modern network infrastructure, both physical and virtual, largely depends on this single interface standard.

Key Advantages of RJ45 in Industrial Networking

- Compact size for tight enclosures and control panels

- Support for high data rates up to 10 Gbps

- Low cost and global availability

- Backwards compatibility with legacy 10/100BASE-T systems

- Available in ruggedized and sealed formats, including IP67-rated versions

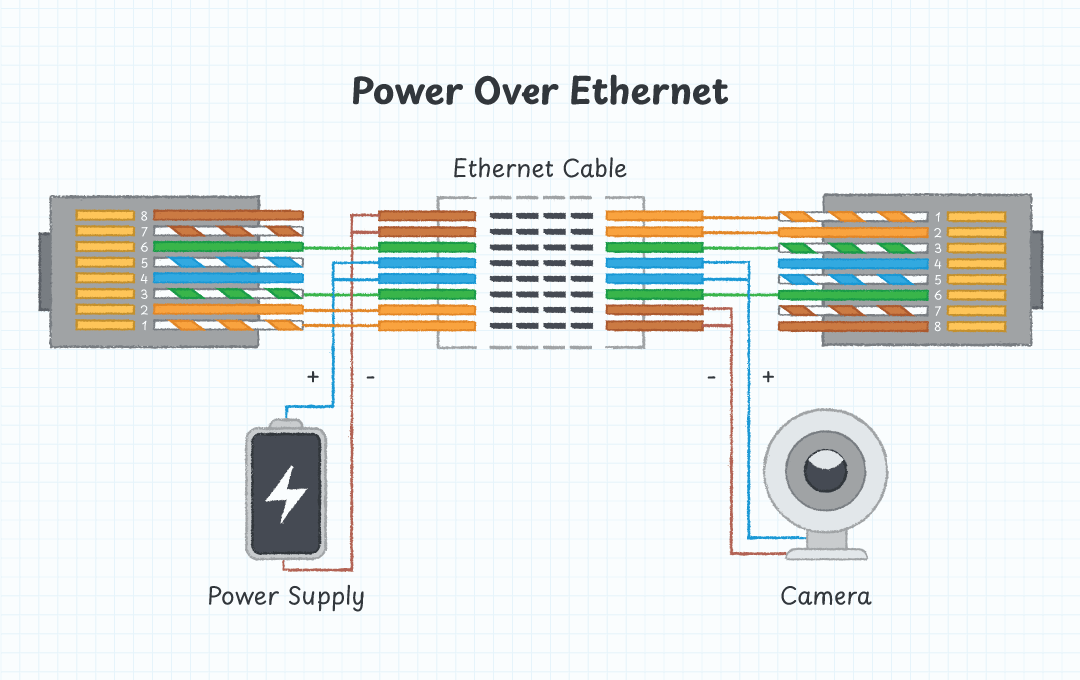

Importantly, it is not just the physical connector that drove RJ45’s success, it is the ecosystem of Ethernet technologies around it. Support for managed switches, VLANs, and Power over Ethernet (PoE) has made RJ45 an essential interface for scalable, modular, and power-efficient networks.

Alternative Ethernet Connectors for Harsh Environments

In addition to the RJ45, other connector types are used for Ethernet, particularly in demanding environments. The M12-style connector is commonly deployed in industrial and harsh environments due to its superior resistance to shock, vibration, and ingress compared to standard RJ45 connectors. Single Pair Ethernet (SPE) is another emerging solution, gaining momentum in industrial and smart building applications. It transmits data over a single twisted pair of conductors and typically uses compact connectors such as M8, M12, or other IEC 63171-compliant interfaces.

What Is Industrial Ethernet? Key Differences from Commercial Ethernet

As industrial systems become more connected, engineers are challenged to link thousands of devices, PLCs, sensors, HMIs, robots, across sprawling facilities. While Ethernet is a proven protocol for commercial networks, traditional Ethernet components are often unfit for industrial use due to environmental and mechanical limitations.

Commercial Ethernet was designed for controlled environments like office buildings and datacenters, where temperature, vibration, and electromagnetic interference (EMI) are minimal. Industrial settings introduce far more demanding conditions: equipment must operate in extreme temperatures, near motors or welders producing EMI, and often in outdoor or mobile environments.

Enhancements in Industrial Ethernet

- Ruggedized cabling

- Sealed connectors

- Expanded temperature ratings

- Protocols tailored for real-time communication

Standard Ethernet cables might fail in environments with dust, oil, or humidity, or under constant vibration from heavy machinery. That’s why industrial Ethernet solutions use ruggedized connectors, such as IP67-rated RJ45 couplers, locking flanges, gaskets, and strain reliefs, to ensure reliable signal integrity and prevent unplanned disconnects.

Most industrial devices require modest data rates, often below 10 Mbps. This enables simpler solutions such as SPE, which supports both data and low-voltage power using just one twisted pair. SPE cables can be terminated into terminal blocks, reducing connector needs, and are ideal for space-constrained or weight-sensitive applications, such as automotive and automation systems.

| Feature | Commercial Ethernet | Industrial Ethernet |

|---|---|---|

| Environment | Offices, datacenters | Factories, outdoor, transport |

| Temperature range | 0–40°C | -40°C to +85°C or more |

| Cable/connector type | Standard Cat5/6, RJ45 | Shielded, sealed, flanged RJ45, M12 |

| Protocols | TCP/IP, VLAN | Time-Sensitive Networking (TSN), PROFINET, EtherNet/IP |

| Vibration/Dust/EMI | Minimal | High resistance required |

| Power Support | Optional PoE | Often requires PoE (PoE+, 4PPoE) |

Table 1: Comparison of commercial and industrial Ethernet.

Finally, industrial Ethernet protocols often incorporate advanced features like Time-Sensitive Networking (TSN), which allows critical messages, such as those controlling safety functions or real-time robotics, to be prioritized over other traffic. While commercial Ethernet can support Quality of Service (QoS), it lacks the determinism required for machine control and motion applications.

What Are the Key Components of an Industrial Ethernet System?

Cables: The Data and Power Highway

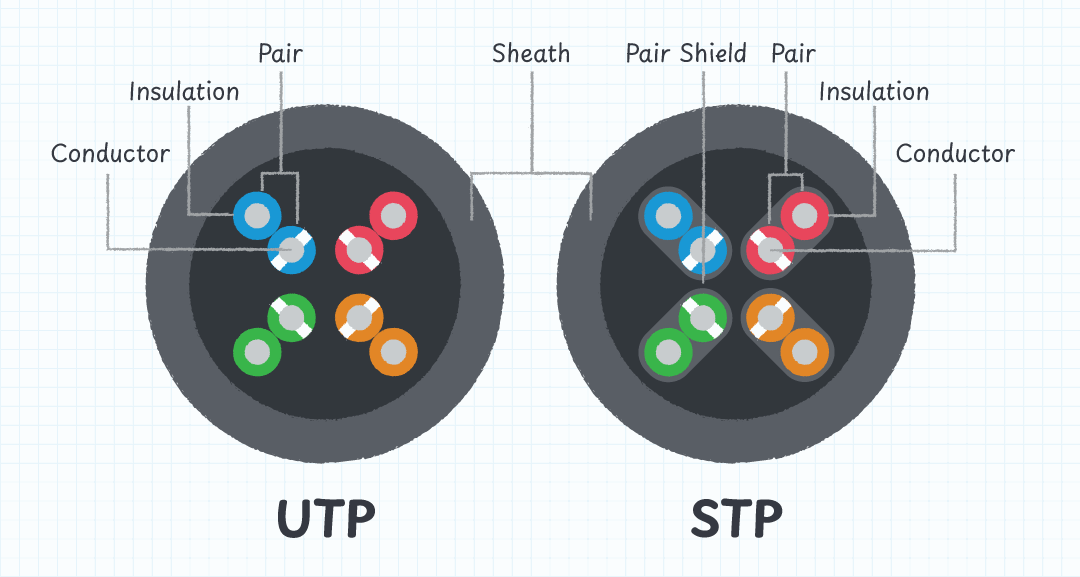

Industrial Ethernet starts with the right cabling. Unlike basic patch cords used in office environments, industrial Ethernet cables must withstand heat, vibration, chemicals, and electromagnetic interference (EMI).

Common Cabling Options Include:

- Category 5e and Category 6/6A cables, which support data rates from 1 Gbps to 10 Gbps and are used for high-bandwidth applications like vision systems and edge computing.

- Shielded Twisted Pair (STP) cables, which reduce EMI and allow longer cable runs, critical for environments with motors, inverters, or radio noise.

- Single Pair Ethernet (SPE), designed for low-speed, low-power applications such as sensors or control loops.

Switches: Directing Traffic in Harsh Environments

Switches serve as the traffic managers of Ethernet systems, ensuring data reaches the correct destination without bottlenecks.

- Unmanaged switches: Offer basic plug-and-play connectivity, ideal for fixed-function or localized systems.

- Managed switches: Support advanced features like VLANs (Virtual Local Area Networks), Quality of Service (QoS), and port mirroring. These tools are essential for segmenting traffic, monitoring diagnostics, and improving real-time performance in larger or time-critical systems.

Industrial-grade switches are often DIN-rail mountable, fanless, and designed to operate across wide temperature ranges.

Connectors: Ruggedized Interfaces for Real-World Conditions

Ethernet connectors are one of the most vulnerable parts of a network. In industrial applications, they must endure dust, vibration, liquids, and corrosive agents, while maintaining a secure signal connection.

Common Connector Features Include:

- Flanges, gaskets, and O-rings for IP67/IP68 sealing against dust and water.

- Locking latches or bolts to prevent accidental disconnects in vibrating environments.

- Shielded housings to prevent EMI or crosstalk.

RJ45 remains the most common connector format, but variants such as M12-X coded connectors are often used in more ruggedized or space-constrained environments.

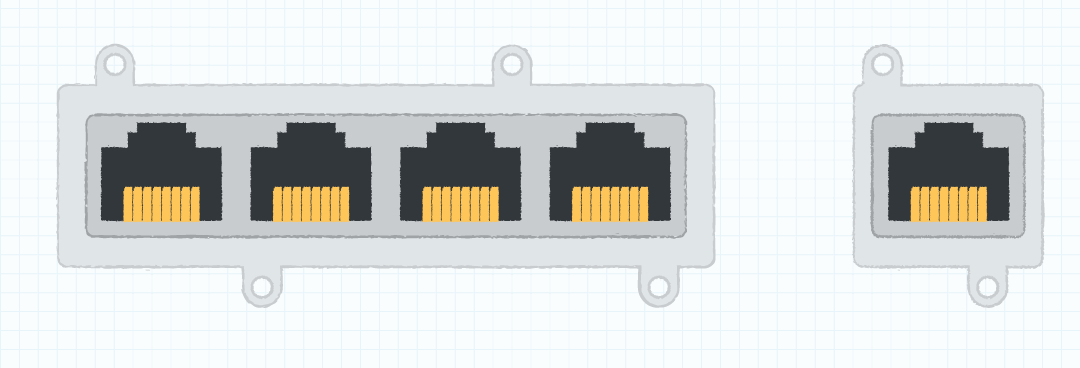

Integrated Connector Modules (ICMs): Simplifying Complex Ethernet Front-Ends

As Ethernet networks incorporate Power over Ethernet (PoE) and expand to support higher speeds, the connector interface must do more than pass signals. It must manage signal integrity, power transmission, and EMI performance, all within limited PCB space.

Integrated Connector Modules (ICMs) address this challenge by combining:

- Ethernet magnetics (isolation transformers)

- Common-mode chokes for EMI suppression

- ESD and surge protection

- Power extraction circuitry for PoE support

These all-in-one components reduce the need for discrete magnetics and filtering components on the main PCB, improving layout efficiency and reliability.

ICMs are ideal for compact or modular designs where board space is limited but performance must remain high, especially in industrial sensors, controllers, or edge computing nodes.

How Integrated Connector Modules (ICMs) Simplify Ethernet Design

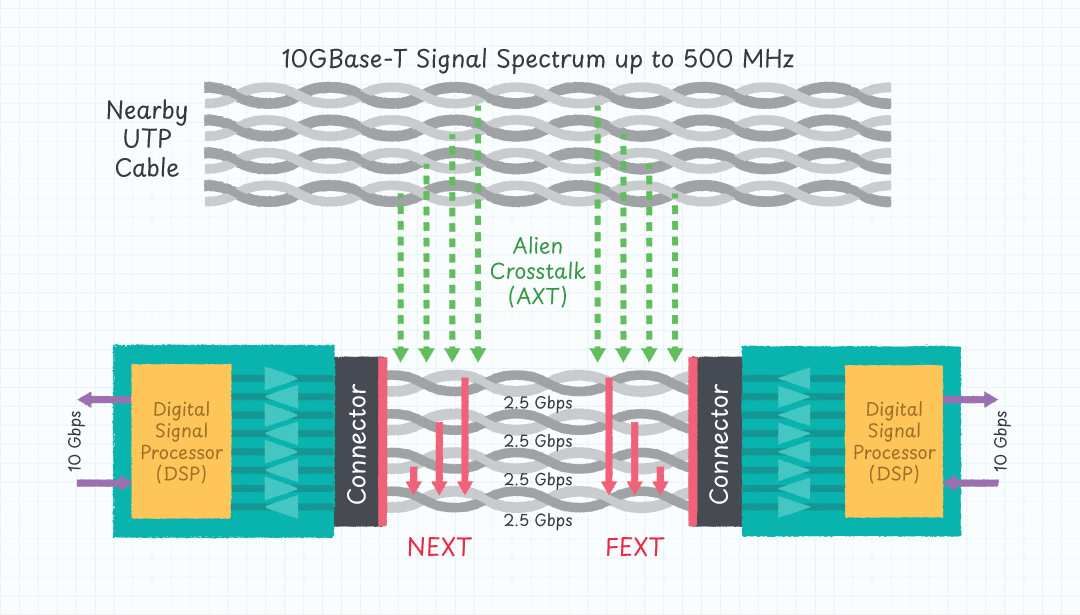

As Ethernet technology continues to evolve, adding support for Power over Ethernet (PoE) and higher data rates up to 10 Gbps, designing a reliable Ethernet interface has become significantly more complex. High-speed signaling, the use of differential twisted pairs, and the need for long cable runs all introduce challenges like crosstalk, signal degradation, and electromagnetic interference (EMI).

To maintain signal integrity, engineers must integrate specialized magnetics, isolation transformers, and common-mode chokes into the Ethernet connector circuit. These components are often implemented using discrete parts, but doing so increases PCB footprint, complicates the layout, and can reduce overall system reliability, especially in high-density or harsh industrial environments.

Integrated Connector Modules (ICMs) solve these challenges by combining all essential components into a single, compact package:

- Signal magnetics for voltage isolation and impedance matching

- Common-mode chokes for EMI suppression

- Built-in ESD and surge protection

- Optional PoE power taps for delivering DC power

Instead of manually designing and routing these circuits, engineers can simply connect an ICM to their Ethernet PHY interface. The ICM handles the filtering, isolation, and protection, while also minimizing the space required on the PCB.

Benefits of ICM Integration

- Smaller, more reliable board layouts

- Improved EMI performance in noisy environments

- Faster time-to-market, with fewer components to validate or source

For industrial applications where size, ruggedness, and reliability are paramount, ICMs offer a high-speed, cost-effective, and future-ready solution that streamlines Ethernet integration across everything from automation controllers to sensor nodes.

The Future of Industrial Ethernet

As industrial systems adopt AI, machine learning, and edge computing, the demand for high-speed, low-latency networking is rapidly increasing. Applications like video analytics, predictive maintenance, and autonomous robotics place significant strain on existing Ethernet infrastructure.

Meanwhile, the rise of Industrial IoT (IIoT) is introducing thousands of low-power devices into industrial networks. While individual sensors may require little bandwidth, scaling these networks creates new challenges for both data traffic and power delivery.

Power over Ethernet (PoE) helps meet these demands by delivering power and data over a single cable, reducing wiring complexity and system costs. However, implementing PoE in compact devices requires careful attention to EMI, magnetics, and board space.

How ICMs Enable Scalable, Future-Ready Networks

Integrated Connector Modules (ICMs) address these challenges by embedding essential Ethernet circuitry, magnetics, filtering, surge protection, and PoE power taps into a single, space-saving component. ICMs make it easier for engineers to design reliable, high-speed, and compact Ethernet interfaces, especially in harsh or high-density environments.

Looking ahead, private 5G networks will complement Ethernet by supporting mobile industrial equipment like AGVs and remote sensors. Even then, ICMs will remain critical at the network edge, enabling connectivity for 5G small cells, IIoT gateways, and ruggedized Ethernet nodes.

Industrial Ethernet is the backbone of the smart factory, and ICMs are the key to scaling it into the future.

Explore our rugged, PoE-ready ICMs to enhance performance, save space, and accelerate your time to market.

.png)