Auto Transformers vs Traditional Transformers

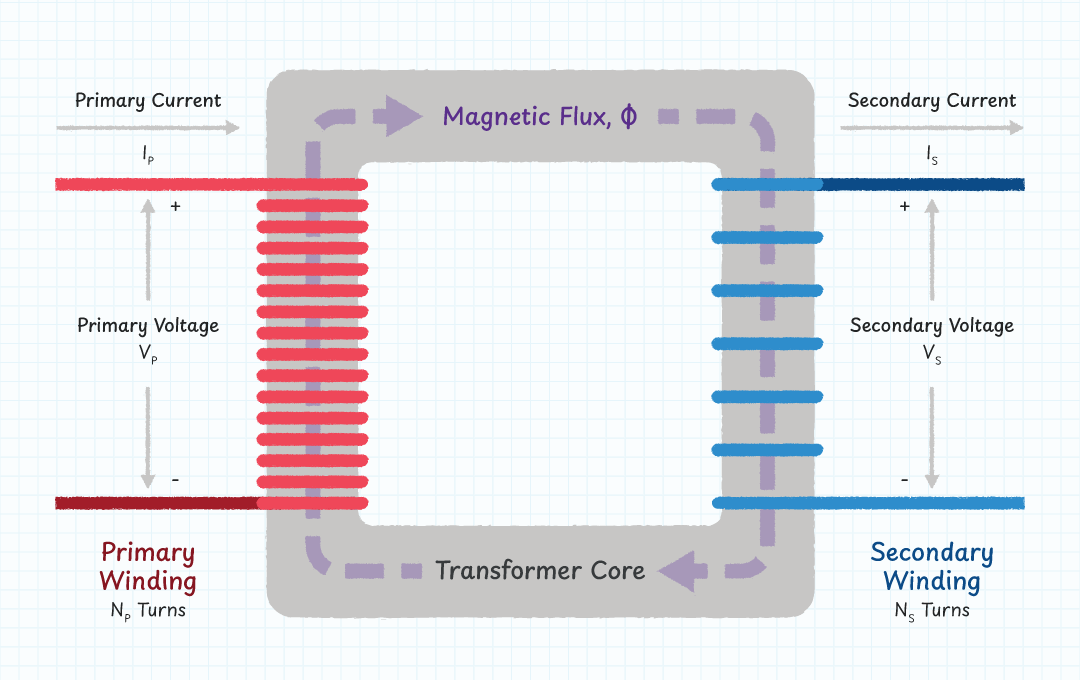

Transformers are foundational components in power electronics, used to convert AC voltages efficiently through the principle of electromagnetic induction. At the heart of every transformer is a magnetic core that channels time-varying magnetic flux, linking multiple windings together. When an alternating current flows through the primary coil, it generates a changing magnetic flux in the core. According to Faraday’s Law, this changing flux induces a voltage in any nearby winding in proportion to the number of turns in that winding:

Equation 1: Induced Voltage

In equation 1, V is the induced voltage, N is the number of coil turns, and dΦ/dt is the rate of change of magnetic flux. In a traditional transformer, the primary and secondary windings are electrically isolated but magnetically coupled through this shared flux (Figure 1). The ratio of voltages between the windings is directly proportional to the turns ratio (Equation 2), enabling the transformer to either step up or step down AC voltages.

Equation 2: Voltage Ratio

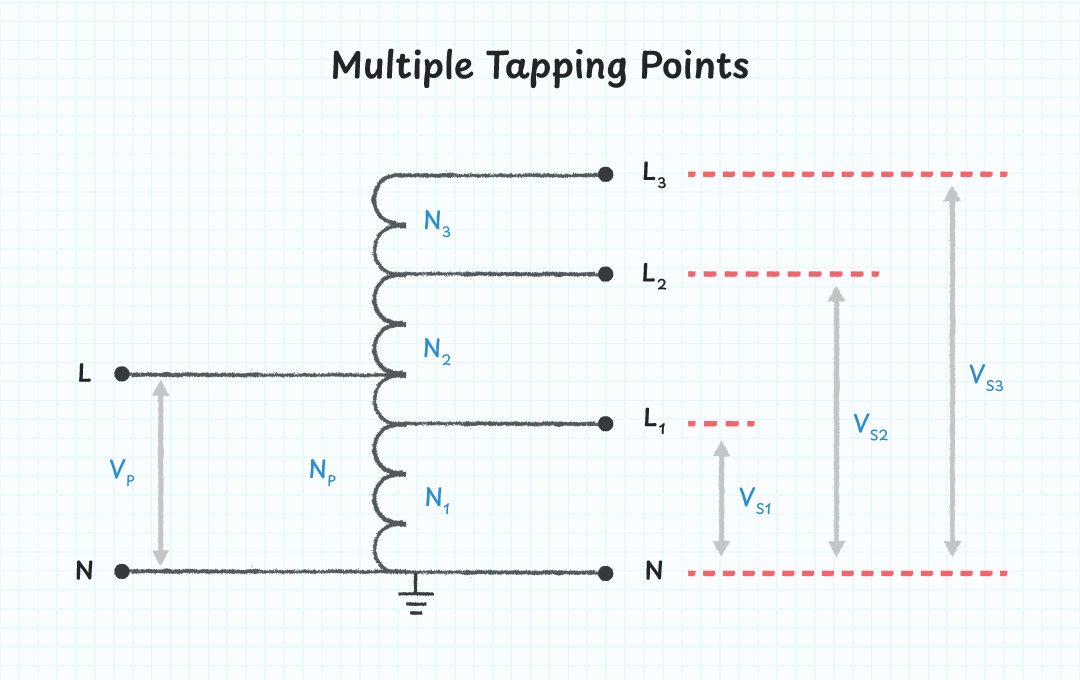

Auto transformers, by contrast, eliminate the need for two separate windings. Instead, they use a single continuous winding with taps at various points, creating shared sections of the coil for both input and output. Although this design removes galvanic isolation between input and output, it preserves the same fundamental operating principle—voltage transformation through magnetic flux linkage, and Equations 1 and 2 remain valid. Because a portion of the winding serves both as primary and secondary, auto transformers can be more compact, efficient, and cost-effective than traditional transformers when isolation is not required.

While often regarded as the potentiometers of the transformer world, unlike traditional potentiometers, which can only divide a given voltage, auto transformers enable the ability to step up or step down an AC voltage. This feature allows for a wide range of voltage adjustments, typically spanning from 40% to 110% of the input voltage, making them an attractive solution for various applications.

In the consumer market, auto transformers are commonly used to adjust voltages from 100 VAC to as high as 250 VAC. For example, they allow electronics designed for one region’s power standard to operate in another. In the United States, they are often employed to fine-tune voltages from 40 VAC to a maximum of 120 VAC, providing flexibility for household or light-duty applications.

In industrial and locomotive markets, auto transformers are typically used for controlling motor speed, balancing electrical loads, and improving energy efficiency. Their compact size and high efficiency make them especially valuable in environments where performance and space optimization are critical.

What is the Difference Between Auto Transformers and Variacs?

Auto transformers come in two primary varieties: selector type and wiper type. Selector type auto transformers feature specific tap points that can be connected to the output, allowing for precise voltage selection. In contrast, wiper type auto transformers, also known as Variacs, can connect to most points of the winding, typically utilizing a carbon brush to make contact. While Variacs are a type of Auto Transformer, not all Auto Transformers are Variacs. While selector types allow for voltage selection at fixed intervals, the resolution is limited to the number and spacing of those tap points. In contrast, Variacs offer near-continuous voltage adjustment through a sliding contact mechanism.

The following table highlights the functional and mechanical differences between selector-type auto transformers and Variacs.

| Feature | Auto Transformer | Variac |

|---|---|---|

| Number of Taps | Fixed (discrete) | Variable (continuous adjustment) |

| Output Control | Step-up/step-down | Smooth adjustment of voltage |

| Mechanical Interface | None | Has a rotary knob or dial |

| Use Case | Power transmission, motor starting | Labs, electronics testing |

| Trade Name | Generic term | Originally a trademark |

What Advantages Do Auto Transformers Have?

One of the most significant advantages of auto transformers is their high electrical efficiency, especially when they are operating near a unity turn ratio. Since the input and output of an auto transformer are not electrically isolated, they can transfer energy directly with minimal losses.

Another advantage of auto transformers is their compact design. Because they only have a single winding, they are much smaller in size and weight than traditional transformers. This makes them ideal for use in applications where space is limited, such as in portable devices or in applications where weight is a critical factor.

The ability of auto transformers to dynamically adjust their voltage output provides another major advantage. This makes them ideal for applications where the voltage supply may change, such as when traveling from one country to another. For example, Auto transformers also provide a valuable solution for travelers who need to adapt electronic devices to different regional voltage standards. For instance, they can convert a 230 VAC supply in Europe to 120 VAC for use in the United States, eliminating the need for a separate transformer or adapter.

Auto transformers are also extremely useful for precise voltage control in power applications, such as AC and DC motor control systems. Their simplicity helps to reduce energy losses while also reducing the overall system cost. These reasons are commonly found in applications such as railway power distribution and industrial systems.

What Challenges Do Auto Transformers Have?

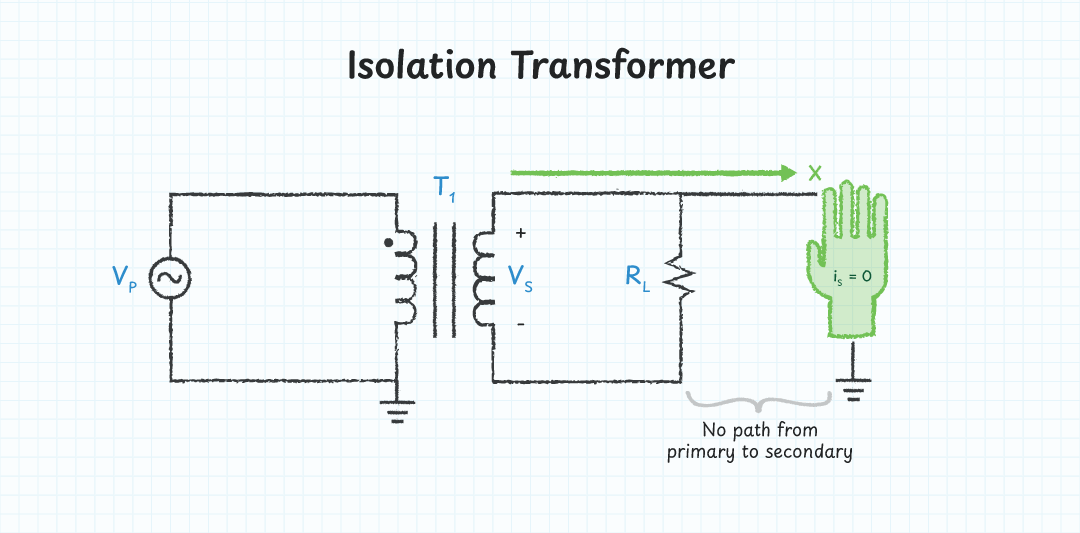

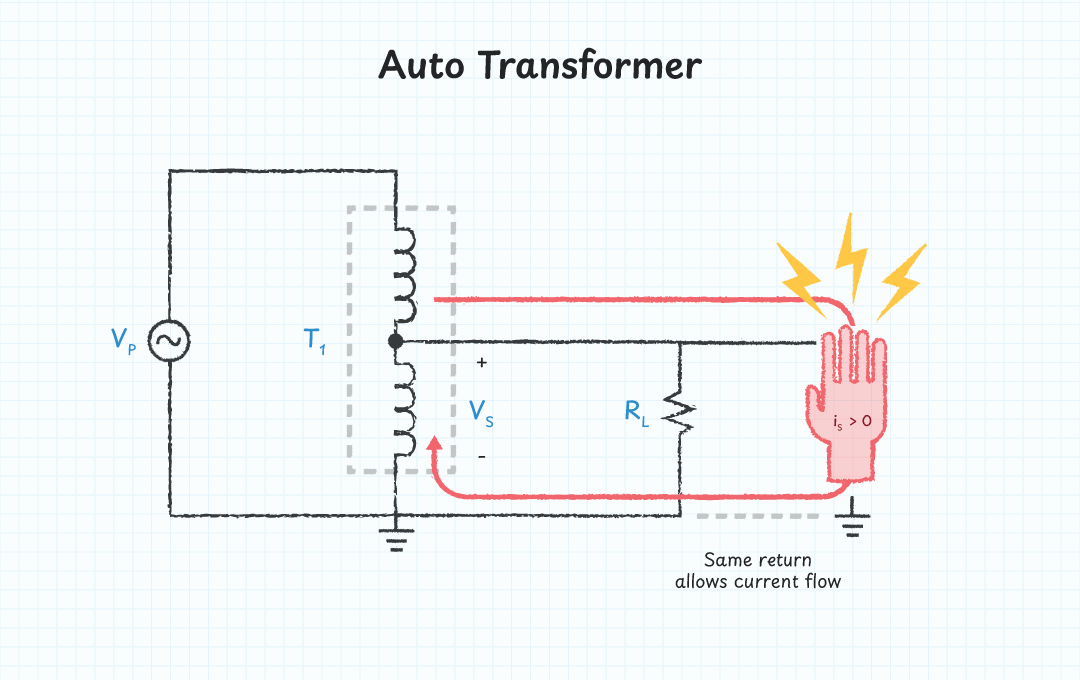

One of the most significant limitations of auto transformers is their lack of electrical isolation between the primary and secondary windings. Unlike traditional transformers, auto transformers have both windings electrically connected, which can make them difficult to use in certain applications. For example, if an auto transformer is used to step down a high-voltage signal to a lower voltage, any faults in the transformer can result in a live output signal, posing a potential shock hazard to connected equipment or users. This can be particularly problematic in applications where the output signal is connected to sensitive equipment, such as electronic circuits.

Another challenge faced by auto transformers is that their lack of isolation means they can be susceptible to electrical noise and interference. As the primary and secondary windings are electrically connected, any noise or interference present on the input signal will also be present on the output signal. This can make it difficult to achieve clean and reliable output signals, especially in applications where high levels of noise and interference are present.

Finally, auto transformers are limited in their ability to provide a wide range of voltage ratios. While traditional transformers can be designed with a wide range of turn ratios (some can be as large as 1000:1), auto transformers are limited to a narrower range of ratios. This can make them less flexible than traditional transformers, especially in applications where a wide range of voltage options are needed.

Where Are Auto Transformers Found?

One of the primary applications for auto transformers is in industrial environments with AC and DC motors. While the speed of an AC motor is independent of the applied voltage (as they are often frequency dependent), auto transformers can be used to help apply higher starting voltages to get motors turning (this is where a larger torque is needed). Once the motor starts turning, the voltage can be lowered and a VFD (variable frequency drive) is used to adjust and maintain the AC motor speed.

Another common application for auto transformers is in substations. In these environments, the isolation between different power feeds is not as critical as it is in other applications, but efficiency is paramount. As auto transformers are highly efficient, they are commonly used in substations to distribute power to different areas of a network. Their ability to easily adjust voltage and power levels also makes them ideal for balancing power distribution across different areas of a network.

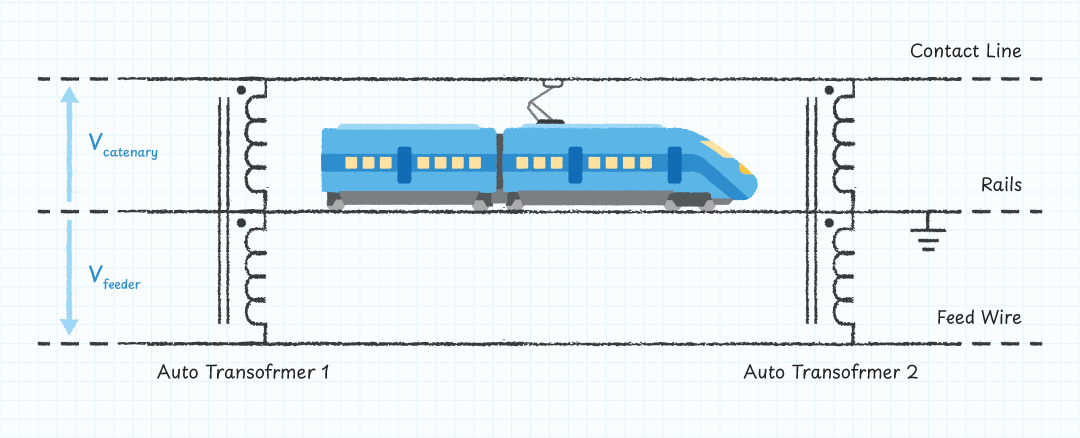

Auto transformers are also widely used in railway systems. In these applications, it is essential that power must be balanced and consistent to prevent damage to the train's electrical systems. The ability of auto transformers to fine-tune output voltages, along with their high-power capabilities, makes them an ideal choice for this environment.

In addition to providing power to trains, auto transformers can also be used to boost voltages on track rails over long distances (more than ten kilometers). This is particularly useful in areas where it is not possible to lay out new power lines, but where a boost in voltage can increase the efficiency of existing lines.

Finally, auto transformers are commonly found in laboratory equipment and testing stations. Their ability to produce a variable output voltage makes them highly versatile, and their high precision and accuracy make them ideal for use in scientific applications. In addition to their use in laboratory equipment, auto transformers are also used in testing stations to simulate different power scenarios. This can be useful for testing equipment in various environments and ensuring it operates correctly in all scenarios.

The Unique Role of Auto Transformers

Auto transformers are highly efficient devices used to adjust AC voltage levels across a range of applications. Unlike traditional transformers, which have a primary and secondary winding, auto transformers have a single winding that serves as both the primary and secondary.

The absence of a secondary winding not only minimizes the overall weight of the transformer but also reduces its manufacturing and integration costs. This lack of isolation between the input and output means that they cannot be used in safety-critical applications, such as medical devices. However, in cases where electrical isolation is not necessary, auto transformers can be a suitable solution.

Overall, auto transformers offer a range of benefits that make them an attractive option for various applications. Their high efficiency, reduced weight, and low cost make them an ideal choice in control AC systems, while their simplicity and ease of integration make them a convenient solution for balancing loads in railway systems.

To learn more, explore Bel’s full range of auto transformers here.

.png)